Exhibitor: Duwe-3D

Booth: 1502

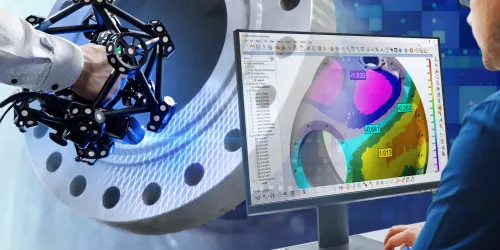

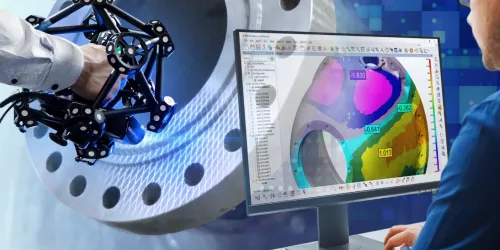

Unleash the Power of Your 3D Measurements

Learn the benefits of retaining your 3D measurement data during this 60-minute virtual and interactive launch event on PolyWorks® 2024. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity.

Unleash the Power of Your 3D Measurements

Learn the benefits of retaining your 3D measurement data during this 60-minute virtual and interactive launch event on PolyWorks® 2024. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity.

Unleash the Power of Your 3D Measurements

Learn the benefits of retaining your 3D measurement data during this 60-minute virtual and interactive launch event on PolyWorks® 2024. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity.

Unleash the Power of Your 3D Measurements

Learn the benefits of retaining your 3D measurement data during this 60-minute virtual and interactive launch event on PolyWorks® 2024. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity.

Unleash the Power of Your 3D Measurements

Learn the benefits of retaining your 3D measurement data during this 60-minute virtual and interactive launch event on PolyWorks® 2024. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity.

Unleash the Power of Your 3D Measurements

Learn the benefits of retaining your 3D measurement data during this 60-minute virtual and interactive launch event on PolyWorks® 2024. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity.

Unleash the Power of Your 3D Measurements

Learn the benefits of retaining your 3D measurement data during this 60-minute virtual and interactive launch event on PolyWorks® 2024. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity.

Unleash the Power of Your 3D Measurements

Learn the benefits of retaining your 3D measurement data during this 60-minute virtual and interactive launch event on PolyWorks® 2024. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity.

Unleash the Power of Your 3D Measurements

Learn the benefits of retaining your 3D measurement data during this 60-minute virtual and interactive launch event on PolyWorks® 2024. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity.

We’ll discuss how the latest innovations in PolyWorks will empower you and your company in building smarter, faster, and easier solutions to transform your hardware and make your 3D measurement data more valuable than ever before.

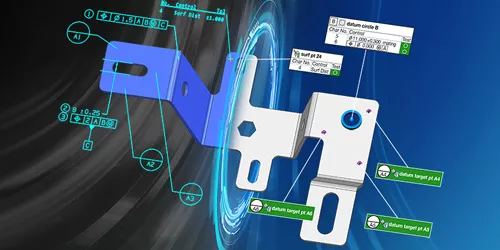

For quality control teams, creating inspection projects from the measurement plan requires time-consuming manual tasks and interpreting dimensional requirements from 2D drawings, 3D CAD models, and additional specifications documents.

Discover how the latest version of the PolyWorks|Inspector™ Gauge R&R workflow lets you certify and improve your 3D measurement process performed through its universal metrology platform.

Learn how to integrate a CAD model revision with PMI within a piece measurement template in PolyWorks|Inspector™ in minutes instead of hours, using our PolyWorks|PMI+Loop™ MBD solution for CAD software.

Discover how the inspection project data lifecycles delivered by the PolyWorks Digital Ecosystem accelerate the engineering phase of a new product, automate the propagation of CAD design changes, and help build strong long-term know-how and expertise within a manufacturing organization.

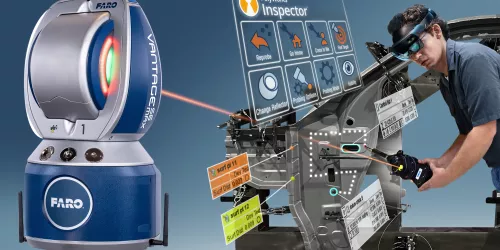

Learn how to successfully build and inspect large-scale precision fixtures and tooling for manufactured parts by combining PolyWorks|Inspector™, the PolyWorks|AR™ mixed reality solution, and the FARO® Vantage Max Laser Tracker.

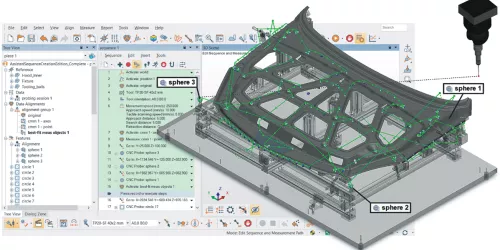

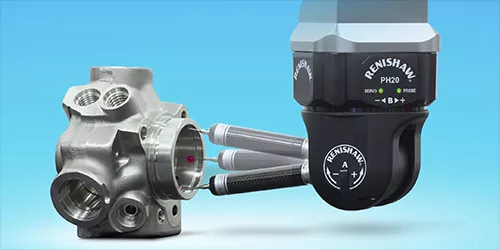

Discover how to create complete CNC CMM measurement sequences in minutes while staying in control with PolyWorks|Inspector™, the universal 3D dimensional analysis and quality control software solution.

Learn how PolyWorks|Inspector™ and Creaform MetraSCAN 3D can improve your measurement workflow and increase your inspection capacity.

See how improve your inspection workflows with repeatable measurement processes and 3D data capture optimized for accuracy and speed by combining PolyWorks|Inspector™ and the FARO® Quantum Max ScanArm.

Discover how to perform multipiece feature-based inspections without a usable CAD representation more efficiently, with probing guidance plus feature scanning guidance and automatic feature extraction, thanks to the measurement guides technology introduced in PolyWorks|Inspector™ 2022.

Transform collision-free 3-axis CNC CMM sequences into optimal 5-axis sequences by efficiently integrating 5-axis moves and head touch probing.