International Automotive Components (IAC) Group Achieves Superior Metrology Flexibility with PolyWorks®

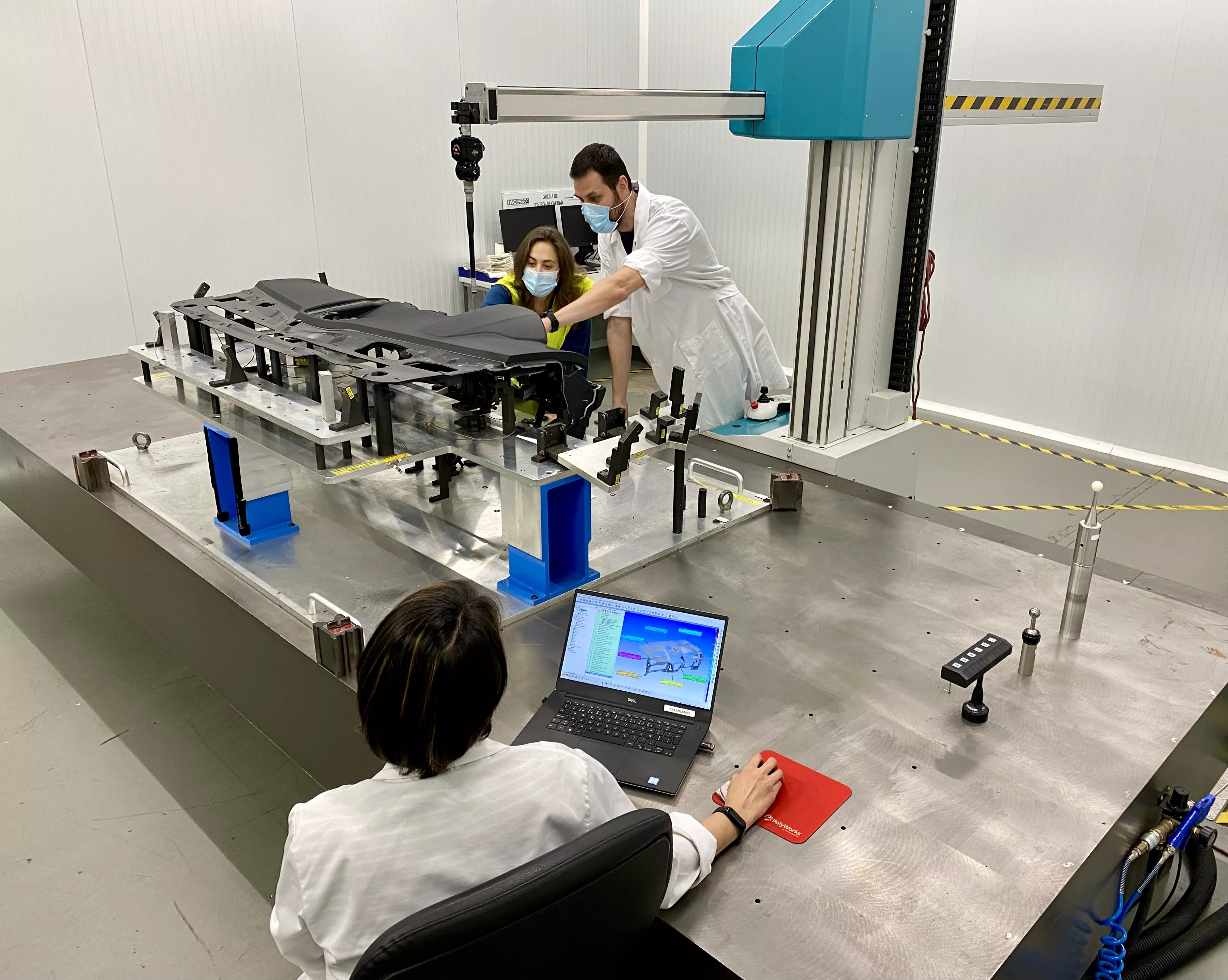

Successful collaboration at the IAC group plant in Agoncillo (La Rioja)

IAC Group, a world leader in automotive interior solutions, has a production plant in the town of Agoncillo (La Rioja) connected to a sequencing centre in Pedrola (Zaragoza). Adopting the universal PolyWorks metrology software platform has resulted in substantial improvements in flexibility, speed and efficiency.

The Challenge

Alicia Ortega, General Supervisor of Quality of IAC Group at the Agoncillo plant and Metrology Manager explains that "we currently have a staff of 560 employees, of which approximately 100 work at the Sequencing Centre in Pedrola. We are Tier 1 and Tier 2 suppliers for customers such as Stellantis, Volkswagen, SEAT, and Ford... We manufacture dashboards, bumpers, spoilers, side skirts, consoles, glove boxes, acoustic barriers... and we have a highly automated paint line."

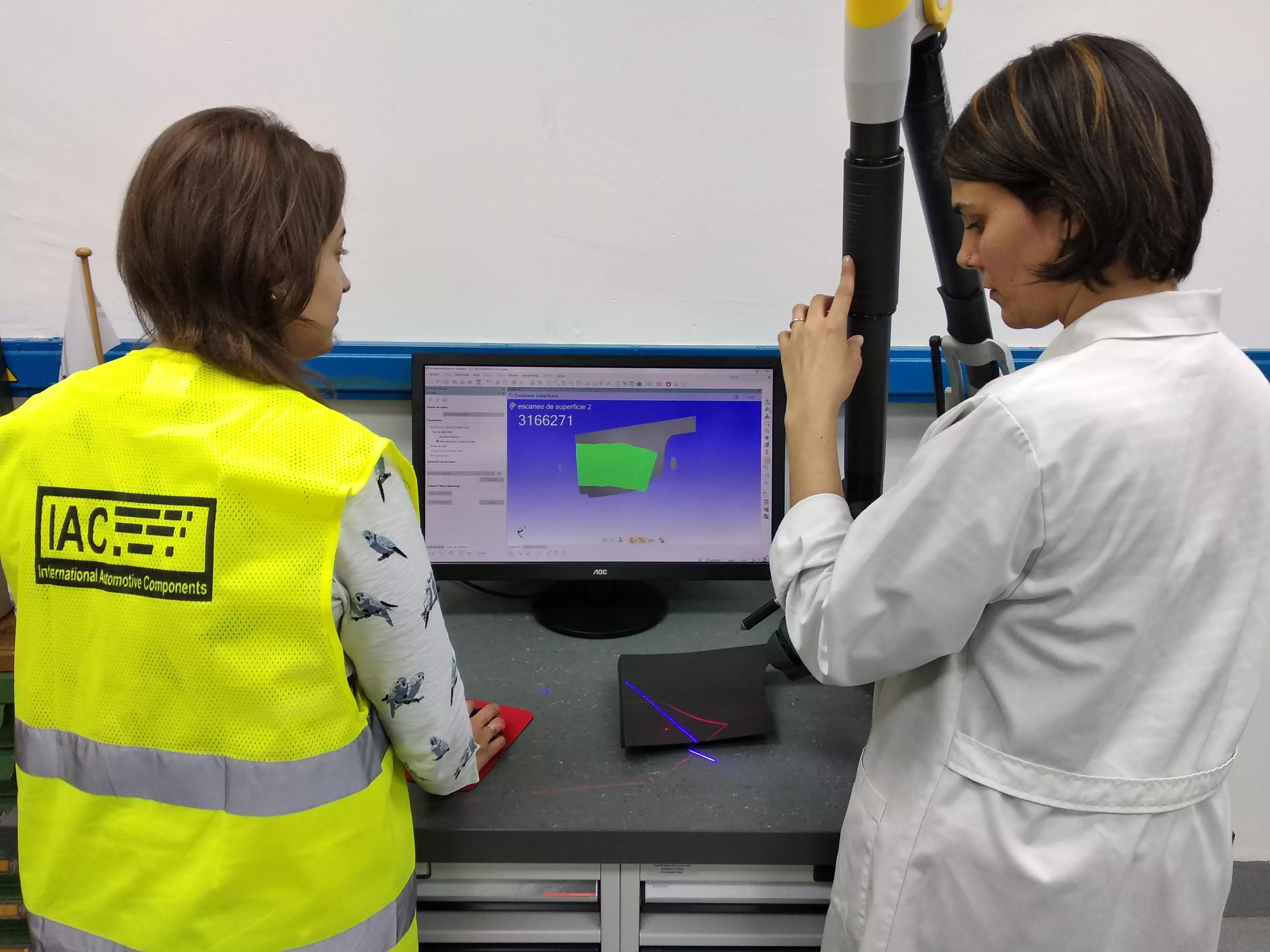

Ortega emphasises that "in the Metrology Laboratory area, we need to be very flexible. We carry out measurements in the laboratory: tests, approvals, adjustments... We have many customers and products, which means that we must have a very high degree of flexibility."

The Solution

"Using the PolyWorks|Inspector™ software, we can, with small changes, adapt the measurement programs from one CNC CMM to another, saving time and increasing efficiency". The collaboration between IAC Group and PolyWorks Europa ressembles that of similar successful experiences in the United States, Mexico, Germany, India, South Africa, and Slovakia. Tania Arellano, Account Executive for PolyWorks Europa, points out that "IAC Group carried out a detailed market study before deciding to implement a single metrology software solution for all its dimensional control processes. Throughout the study, we accompanied them with demonstrations and tests in their laboratory. Once they opted for our solution, we provided advanced CMM and GD&T training. They started implementing PolyWorks|Inspector with 3 measurement devices and have ended up extending it to the entire metrology laboratory."

Both PolyWorks Europa and IAC agree that metrology data connectivity is key.

The Benefits

"A very close collaboration and the use of our shared knowledge have resulted in a high fulfilment of expectations." IAC Group’s Quality Manager, Alicia Ortega, highlights that "measuring in parallel on several CMMs has helped us to significantly improve customer response time, which is now quite fast. It has allowed us to greatly streamline certain operations, optimizing the output of our metrologists and the use of our measurement equipment. We can clearly speak of an Industry 4.0 project, which confirms a trend of delegation of metrology tasks to suppliers by OEMs. There is also a growing need in the industry for data collection and processing in real time."

Estela Aparicio, Metrology specialist at IAC Group says: "I had not worked with this software before, but it is very easy to use and very simple when looking for solutions to measurement problems on the spot." Also, the specialist in the 3D Measurement Area, Rafael González, points out that "it is a very powerful software with a very intuitive interface." What all PolyWorks|Inspector users agree on is the superior technical support from the PolyWorks Europa team in Spain: "Above all, it was vital when we started using the software, which is when there are more questions. You call and they take care of you right away, which is great support."

As for future projects, both PolyWorks Europa and IAC agree that metrology data connectivity is key. Along these lines, InnovMetric has just launched PolyWorks|DataLoop™, a data management solution that offers a digital collaboration platform: it facilitates teamwork and contributes to the digital transformation of metrology processes.